Why K & M airporttechnik is just the right partner for you

K & M airporttechnik – the experts in aircraft recovery

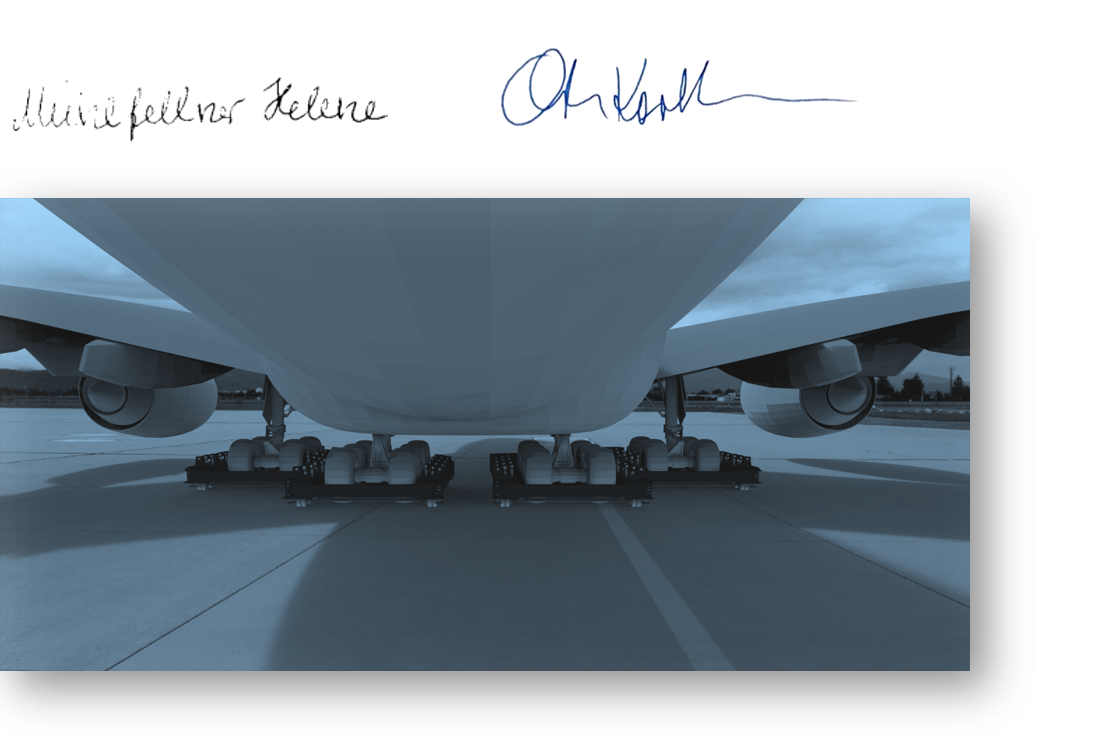

Necessity is the mother of invention – that describes in the best way how the company K & M airporttechnik was established by their two foundersWalter Mühlfellner and Franz Körbler in 2007. It all started with an accident at Graz Airport, where an aircraft should have been rescued in the fastest way possible. However the endeavour seemed to be more difficult than expected, because the necessary recovery equipment was basically non existent.

Reason enough for the two bright minds to get together and start inventing a suitable solution that would permanently change the future and security at airports across Europe. After all, those two together combine over 80 years of experience at the airport and at the fire brigade.

The prototype of a dolly was created and came into use shortly afterwards at Graz Airport. With vast success, as it seemed. As a result, Vienna Airport also became aware of this innovative implementation of a rescue dolly, that had never been seen before.

After a few adaptations the next dolly went directly to the capital of Austria. Hence the foundation for K & M airporttechnik was layed. Shortly afterwards, the entire Austrian market was supplied with the recovery vehicles of the two-man company which is based in a small village named Werndorf. And Austria should only be just the beginning. Far beyond home borders, the numerous products, developed by the two founders, are nowadays used at airports throughout Europe.

The recipe for success of K & M airporttechnik

The dollys and various products of K & M airporttechnik are currently being used successfully at the airports in France – Cannes, Münster, Osnabrück, Ljubljana, Ibiza, St. Gallen, Montpellier, Us Airforce Airbase Turkey, Madrid, Barcelona, Palma and Hanover.

Policy of quality

Our continuous improvement process for recovery procedures and trainings as well as our

long-term technical know-how ensure our product quality on the one hand and have led to

the fact that we are also seen as technical consultants for recovery solutions by our

customers.

Customer solutions are developed in close cooperation not only cost-oriented but also with

regard to easiest handling of the products, lowest maintenance effort and effectiveness.

This also includes the highest quality demands on our partners and suppliers. These highest

demands are consistently implemented in all areas of the purchase of products, starting with

the necessary tools for the assembly of our products on site up to the bonding of the

recovery cars with certified foils.

Product improvements are discussed internally with the on-site experience gained in the

practical application of our products and the experience and suggestions of our customers,

and are continuously optimized. Modern tools such as the use of 3D technology in the design

process as well as CAM-controlled production processes support us in planning and

production.

Werndorf, 2024, 1st of March